Sometimes big ideas get small coverage. Unfortunately, that was the case with President Trump’s March 15 trip to Michigan, in which he raised an important idea—arguably the most important economic-policy idea in U.S. history—and yet his words received almost no attention.

Perhaps that was inevitable, because, as we all know, White House reporters these days have been focused on the healthcare bill, and the new proposed budget, and various allegations about hacking and tapping.

Yet here’s a Virgilian prediction: Long after the sound and fury about those other controversies have passed away, Trump’s big point on the economy will be remembered. Indeed, it’s likely that the pro-growth, pro-jobs, pro-profits alliance that Trump espouses will become permanently embedded in Republican thinking—and, quite possibly, Democratic thinking as well.

So what, exactly, did Trump say in his brief speech at Willow Run, the former factory site in Ypsilanti Township, Michigan? What was the larger message to the leaders of the Big Three automakers—Ford, Fiat-Chrysler, General Motors—as well as the head of the United Auto Workers, the governor, and other luminaries?

President Donald Trump speaks at the American Center for Mobility, Wednesday, March 15, 2017, in Ypsilanti Township, Mich. (AP Photo/Paul Sancya)

Trump started out by taking his listeners back to a time when America was at the zenith of its power. That was World War II. Back then, Americans were more confident and more united; they were all in this together, aiming to defeat Hitler abroad and, at the same time, defeat the Depression at home.

And no state better epitomized that “Can Do” ethos than Michigan. The Wolverine State was the manufacturing hub of the country, which meant that it was the manufacturing hub of the world. And it was that manufacturing strength, of course, that enabled us to defeat the Axis powers in less than four years. Trump recalled those years of American strength, and even included a wistful note about the manufacturing mojo that’s been lost in recent decades:

Great Americans of all backgrounds built the Arsenal of Democracy — including the legendary Rosie the Riveter, who worked here at Willow Run. . . . Seventy-five years ago, during the Second World War, thousands of American workers filled this very building to build the great new airplane: the B-24 Liberator. At peak production–listen to this, it’s not the country that we’ve been watching over the last 20 years—they were building one B-24 every single hour.

Without a doubt, Willow Run was an immense achievement. In June 1941, it was just a field, 30 miles outside of Detroit. And yet by September of the the following year, it was producing B-24 Liberator bombers, each with 488,193 parts, capable of delivering four tons of ordnance on a target nearly three thousand miles. By 1945, Willow Run had produced nearly 9,000 of these fearsome birds of war. And oh, by the way, it employed 42,000 men, and women, at its peak—including Rosie the Riveter (even if Rosie’s story is, shall we say, clouded by legend).

Henry Ford watching women drill and rivet the center wing section of a B-24 at the Ford Motor Co. Willow Run Bomber Plant, 1942. (Source: The Henry Ford/Flickr)

Women riveting a B-24, Willow Run Plant, 1944. (Source: The Henry Ford/Flickr)

Jane Wanley and her sister Martha Rohder riveting at the Willow Run Plant, 1943. (Source: The Henry Ford/Flickr)

Men assembling the cockpit of a B-24 at the Willow Run Bomber Plant, 1942. (Source: The Henry Ford/Flickr)

The B-24 assembly line, Willow Run Plant, 1943. (Source: The Henry Ford/Flickr)

Actress Jeanette MacDonald signing a B-24 Liberator at the Willow Run Bomber Plant, March 1943. (Source: The Henry Ford/Flickr)

Yes, Willow Run is a stirring tale of get-up-and-go war production, and yet it is just one of many. In WWII, the overall American industrial war effort also produced, for example, more than 100,000 armored vehicles, 300,000 airplanes, and 41 billion rounds of ammunition. It takes nothing away from the courage of our fighting men in WWII to say that their job of victory was made infinitely easier by the typhoon of steel that they could unleash on the enemy.

B-24 Liberator bombers of the U.S. 8th Air Force flying towards their targets in occupied Europe on Aug. 12, 1943. (AP Photo)

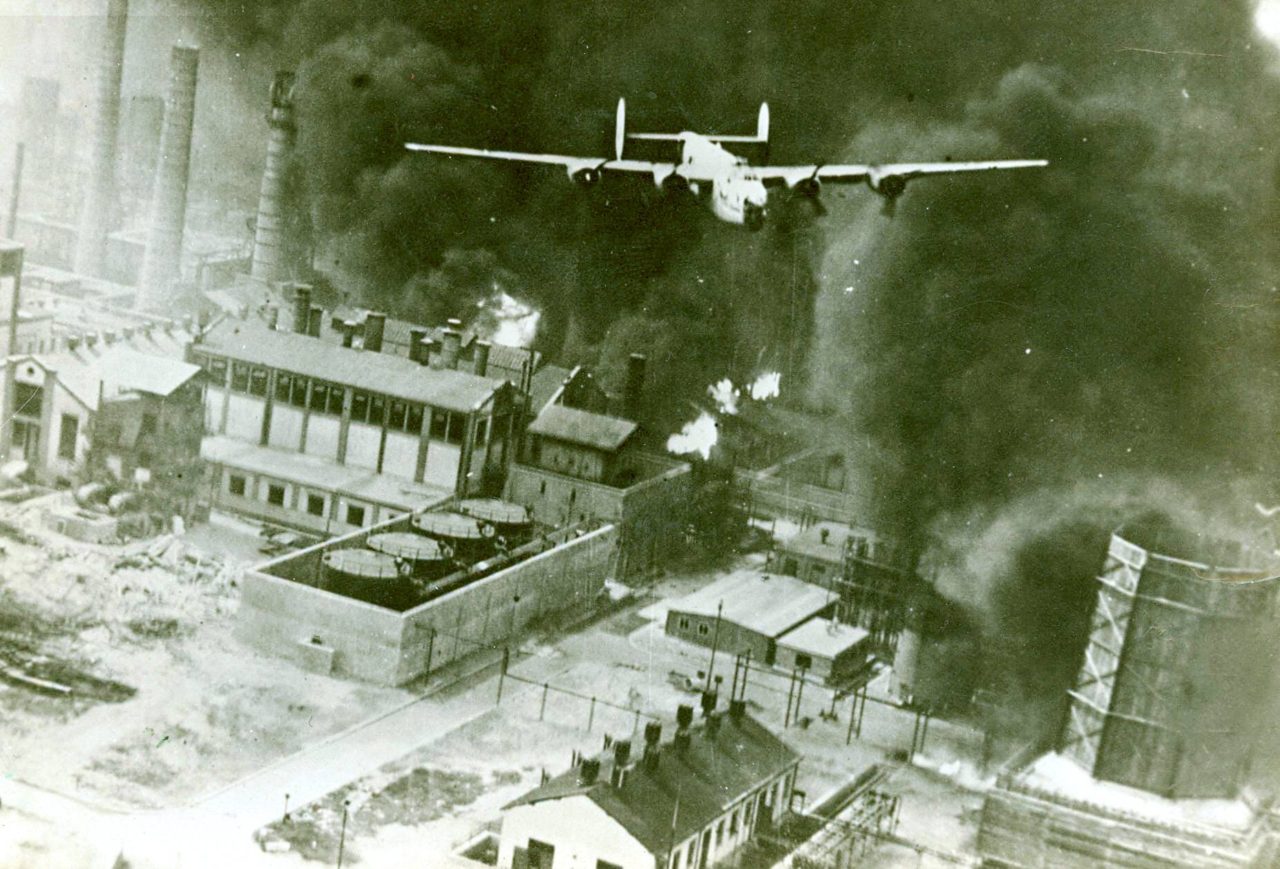

A B-24 flying over a burning oil refinery at Ploiești, Romania, during Operation Tidal Wave, August 1, 1943. (Source: Wikimedia Commons)

A B-24 Liberator of the U.S. Army 8th Air Forces bombs a vital oil refinery at Wedel-Schulau, in the outskirts of German port and city Hamburg, on December 1, 1944. (AP Photo)

So how did Uncle Sam achieve that miracle of production? The most obvious answer is that we had the industrial resources in place before the war, and so it was simply a case of ramping them up during the war. In 1939, for example, we produced twice as much steel as Hitler’s Germany, and our advantage grew during the war years, in no small part because B-24s, and other bombers, were smashing Nazi factories.

And yet as the complexity of the B-24 reminds us, effective production is more than just gross aggregates; each weapon, each airplane, must be designed and assembled properly. And so as we think about the nearly half-million components of a B-24, we can learn a lot from the 1956 memoir of Charles E. Sorenson, a top Ford Motor Company executive who became the chief of Willow Run. In that book, Sorenson outlines what it was like to build and operate what was then the largest shop floor in the world.

As an aside, we can note that the title of Sorenson’s tome, My Forty Years with Ford, takes us back to another facet of that bygone era, when a well-paid employee was loyal to a company and the company, in turn, was loyal to the employee. It’s in such a context—that is, a rich “corporate culture” that nurtures talent—that employees tend to do their best for their company, and for their country.

Of course, for every motivated white-collar executive, there were thousands of skilled blue-collar workers, and they were key, too. We can say: This is how quality manufacturing gets done—that is when employers and employees are so invested that they both work extra hard to improve the product.

The point here, to be sure, is not to sugarcoat that era; along the way, there were plenty of strikes, slowdowns, and other kinds of workplace trouble. And yet the proof is in the pudding: The B-24s got built, and we won the war.

So now we can see why Trump was smart to invoke the glory days of Willow Run.

Even seven decades later, the story of Detroit during WWII impresses and inspires.

In fact, that same productive spirit continued after the war, when Willow Run was converted to domestic auto production; that was the beginning of the post-war boom—that is, when factories for wartime production instantly becoming factories for peacetime production.

The last B-24 bomber made at the Willow Run Plant, June 28, 1945. (Source: The Henry Ford/Flickr)

It’s been estimated that the U.S. government spent a trillion dollars, adjusted for inflation, to build all those defense plants during the war, and yet after VE Day and VJ Day, those now-surplus facilities were sold off to private manufacturers for just pennies on the dollar. Critics complained that it was a giant giveaway to corporate America, but consumers were just happy to have new cars, toasters, and TV sets.

Another decisive moment in the building of the post-war American Dream came in 1950, when the United Auto Workers settled a labor dispute with General Motors. It was a generous deal, setting a pattern of high wages for high productivity; it came to be known as the “Treaty of Detroit.”

History tells us that the Treaty, and others like it across the country, were a success. In those years, the American economy demonstrated that high wages, high growth, and high profits could go hand in hand. So perhaps it’s little wonder that Trump has cited the late 1940s and 1950s as one of his two favorite periods of U.S. history.

Indeed, as a look at historical data from the St. Louis Federal Reserve shows, in the 40s, 50s, and 60s, GDP growth was routinely three or four percent a year, or more.

By contrast, in the fourth quarter of 2016, growth was just 1.9 percent; as many observers have noted, Barack Obama was the first president in U.S. history never to have achieved three percent growth in a single year of his time in office. And according the Atlanta Fed, growth in the first quarter of 2017 could be just .9 percent.

So what happened? Where did our manufacturing mojo go? And what about our prosperity? As we survey the causes of damage, probably the biggest single culprit is globalization. It was globalization that broke up the old alliance of capital and labor.

To be sure, that alliance might not have always seemed like an alliance—it was uncomfortable at times, even hostile, on both sides. Yet it was always based on a blunt reality; the two sides were stuck with each other, and there was no other place else to go.

But then, with the coming of worldwide free trade and outsourcing, capital discovered, to its delight, that it had a new option: It could locate or relocate factories anywhere in the world. (And to its further delight, capital discovered that the U.S. military would likely protect its overseas investments, too.)

Thus it is that today, the U.S., having led the world in vehicle production for most of the 20th century, now finds itself ranked fourth in total passenger car production, producing less than 20 percent of the number of autos as China.

In the meantime, this data from the Economic Policy Institute underscores what happened to workers as a result: Whereas from 1948 to 1973, productivity and wages moved up rapidly in lockstep, since then, productivity has continued to grow, and yet wages have grown hardly at all. Thus we can see the result of globalization on the U.S.: slower economic growth, as value-adding manufacturing has fled, and yet for immobile workers, the impact was worse—a severe stagnation of wages.

Trump’s White House strategist, Stephen K. Bannon, nailed it in an interview last November: “The globalists gutted the American working class and created a middle class in Asia.”

So now comes President Trump, determined to undo the ill-effects of globalization by invoking, once again, the winning spirit of American nationalism. As he said in Willow Run:

You’ve heard me say the words, and I’ll repeat them, right now: Buy American and Hire American. It’s not just a motto, it’s a pledge. It’s a pledge to the working people of this country.

In fact, as we all know, even before entering the White House, Trump was deeply engaged in successful efforts to keep jobs in the U.S.

The March 17, 2017 full-page ad in the Wall Street Journal on behalf of the 7 million American workers in the automotive sector.

Yet of course, helping the economy, and workers, requires more than just ad hoc efforts, valuable as those might be. It also requires better policies, which the Trump administration is pushing, and important stakeholders are taking notice:

On March 17, the two largest motor-vehicle trade associations took out a full-page ad in The Wall Street Journal, thanking Trump for ordering the Environmental Protection Agency and the Department of Transportation to stop escalating the red tape on fuel economy and greenhouse gas standards. As the ad says, “7 Million Thanks to President Trump”—that being the number of American workers in the automotive sector.

In addition, Trump is working on the problem in ways that transcend the usual issues of taxes and regulation. Indeed, it’s fair to say that Trump seems to be moving toward a new philosophy for the economy. As he said in Michigan:

We must embrace a new economic model. Let’s call it the “American Model.”

Okay, maybe it’s not quite a new model; maybe it’s better to say it’s a classic model.

To Virgil’s ear, Trump’s use of the phrase “American Model” sounds a lot like an earlier expression of U.S. economic nationalism, “American System.” And that, of course, was the coinage of Henry Clay (1777-1852), who, after Alexander Hamilton, stands as the greatest champion of American industry in the 19th century.

Yet let’s let Trump himself describe what he has in mind:

Under this system, we will reduce burdens on our companies and on our businesses. But, in exchange, companies must hire and grow in America. They have to hire and grow in our country. That is how we will succeed and grow together–American workers and American industry side by side.

We can note immediately that the third word Trump used was “system”; it’s obvious that Clay’s American System is very much in the mix. Indeed, Trump’s idea of owners and workers joined together recalls a once-hugely influential 1851 book by the economist Henry Charles Carey, The Harmony of Interests: Agricultural, Manufacturing, and Commercial.

Of course, some might wonder if economic ideas from two centuries ago are still relevant. Yet in fact, they are very relevant.

Yes, the basics of the Hamilton-Clay-Carey vision are timeless. Why? Because a country needs manufacturing at home, not only for its prosperity, but also for its security. After all, in a time of crisis or war, the U.S. needs to be self-sufficient; that is, we wouldn’t be able to rely on imports for needed materiel.

Yet to have the needed manufacturing at home, a country needs all the basics: a good trade policy, yes, but also, a positive business climate, a strong workforce, and robust infrastructure.

Furthermore, as Trump suggested in Michigan, a country also needs a spirit of common purpose and patriotism that inspires owners and workers to pitch in to help each other. These were the lessons of WWII, and Trump deserves great credit for bringing them to the fore—even if the Main Stream Media didn’t seem to notice or care.

So yes, it’s true: Trump’s “American Model” has yet to be truly fleshed out, let alone implemented. And yet Virgil is optimistic about the idea’s future, because, as we have seen, it has such a glorious past.

Indeed, Virgil rather suspects that smarter Democrats will seek to grab hold of the same economic-nationalist idea; it’s in their political heritage, too: It was, after all, a great Democratic president, Franklin D. Roosevelt, who was on hand in 1942 to kick off the beginning of Willow Run’s production line.

Henry Ford and President Franklin Roosevelt touring Willow Run Bomber Plant with Charles Sorensen, September 18, 1942. (Source: The Henry Ford/Flickr)

In the meantime, to cite a pair of bad counter-examples, we might ask ourselves: Will any Democratic president in the future be as aloof as were Bill Clinton and Barack Obama on the issue of American jobs going overseas? Answer: Probably not. Virgil’s bet is that Trump has so demonstrated the political value of hands-on action for jobs that future Democrats in the White House will follow his precedent.

Yet whether the Democrats are on board or not, Republicans should think hard about the vision Trump is putting forth, even if it is at odds with the doctrinaire globo-libertarianism that has so long predominated.

For America, the stakes are high. Ultimately, both our prosperity and security as a country depend on our willingness to come together around the idea of revived domestic production.

To be sure, as a nation, we’re a long way from where we need to be. Yet in the meantime, if we need inspiration for the trek ahead, we can think about Willow Run, its leader, Charles Sorenson, and its most famous worker, Rosie the Riveter.

Back then, as a team, they knew how to work together to win.

COMMENTS

Please let us know if you're having issues with commenting.