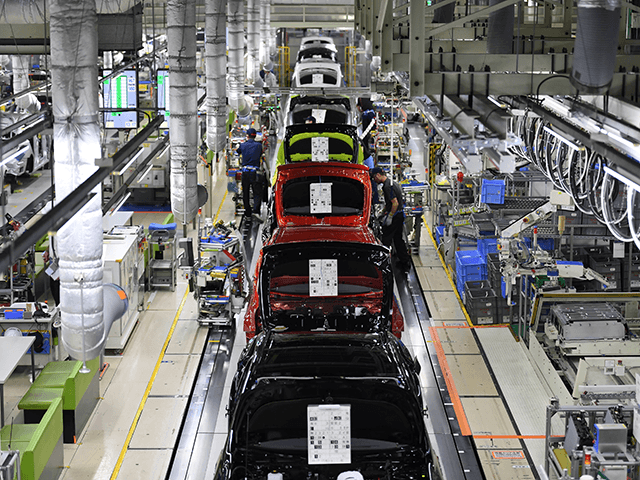

Toyota Motor Corp. will suspend the operation of 14 production lines across eight factories in Japan for nearly one week later this month as part of the Japanese automaker’s effort to cope with a microchip shortage caused by a month-plus Chinese coronavirus lockdown of Shanghai, China, Kyodo News reported Wednesday.

“[A]s a result of the lockdown in Shanghai, China, we have decided to additionally suspend operations of 14 lines at 8 plants in Japan from May 16 (Mon) to May 21 (Sat),” Toyota said in a press release May 10.

“We had announced that our global production plan for May would be approximately 750,000 units, but due to the impact of the lockdown, it is expected to be around 700,000 units,” the automobile manufacturer revealed.

Health workers in protective gear walk out from a blocked off area after spraying disinfectant in Shanghai’s Huangpu district. (STR/AFP via Getty Images)

Toyota acknowledged that the production suspensions were a direct result of “[t]he shortage of semiconductors … [which] are making it difficult to look several months ahead.”

#Toyota to halt 8 plants in Japan due to Shanghai COVID-19 #lockdownshttps://t.co/2oUu7sjTal

— Kyodo News | Japan (@kyodo_english) May 10, 2022

Toyota’s latest production adjustments marked the second time in recent weeks that the company’s output has been negatively impacted by a microchip shortage tied to Shanghai’s lockdown, Kyodo News noted Wednesday.

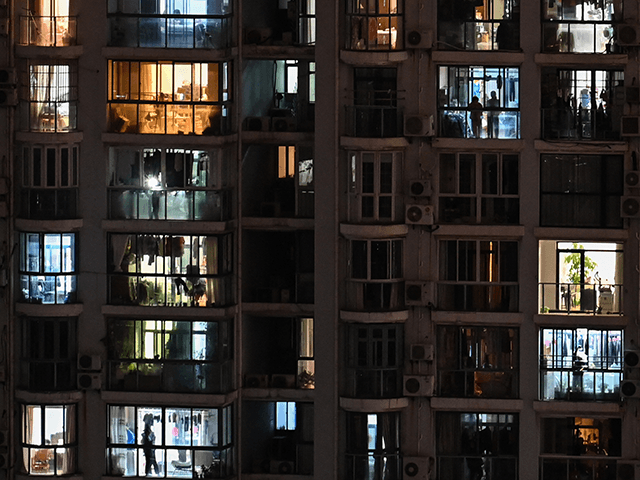

This photo taken on April 29, 2022 shows residential units during a Covid-19 lockdown in the Jing’an district in Shanghai. (HECTOR RETAMAL/AFP via Getty Images)

“The partial suspension will increase the number of Toyota factories in Japan affected to 12. The company, which runs a total of 14 factories in Japan, already said last month it would halt some operations on 10 lines at nine plants in May due to a shortage of semiconductors,” the Tokyo-based news agency observed.

Toyota, which is the world’s number one automaker by sales, cautioned its investors on Wednesday that “unprecedented” spikes in the costs of raw materials and increased logistics costs (both largely due to the Chinese coronavirus pandemic) could cut the company’s full-year profit by as much as 20 percent.

Reuters paraphrased Toyota as saying on May 11 it “expects materials costs to more than double to 1.45 trillion yen ($11.1 billion) in the fiscal year that started in April, which it expected to deal with by switching to lower-cost materials.”

Toyota to slash production plan, suspend some domestic operation due to COVID lockdown in China https://t.co/DUC68VCjgT pic.twitter.com/qrQfy4xs9K

— Reuters (@Reuters) May 10, 2022

“Since the price of materials is rising, we need to work to reduce the amount of materials we use as much as possible and to replace them with less expensive materials,” Toyota Chief Financial Officer (CFO) Kenta Kon told reporters at a press briefing on May 11.

Shanghai has been under a city-wide lockdown order since April 5 to contain its latest epidemic of the Chinese coronavirus. The movement restrictions have hampered production at nearly all of the city’s local factories, which include several dedicated to the manufacture of semiconductors. Shanghai is considered a top financial hub, both within China and globally. The metropolis contains hundreds of manufacturing plants owned by multinational companies, such as Toyota, and additionally houses the world’s busiest shipping container port. These attributes mean Shanghai’s standstill over the past month has caused not just raw material shortages across industries but also logistical bottlenecks that have frustrated companies worldwide.

In response to the pandemic-induced global supply chain crisis, which has been greatly exacerbated by Shanghai’s ongoing lockdown, the city’s Communist Party-run government announced an extraordinary measure on April 15 that allowed factories to resume limited production if their workers lived on-site at the plants and maintained a so-called “closed-loop” system of management to prevent Chinese coronavirus transmission.

COMMENTS

Please let us know if you're having issues with commenting.